INDUSTRIES

POY-FDY DOFFER

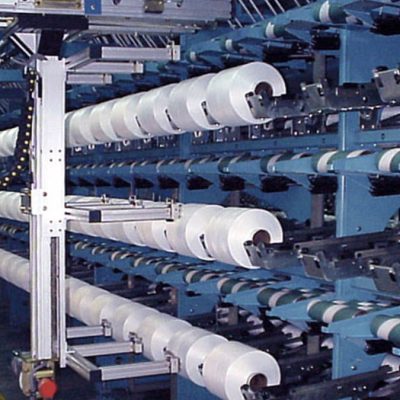

Machines for doffing yarn

bobbins from automatic winders

The Doffer is the Salmoiraghi machine for pick-up of yarn bobbins from winders and their transfer to the pins of overhead transport vehicles (Shuttles) or ground carts for subsequent automated handling.

The Doffer range is comprised of various models capable to interface with any winder type, including the latest twin mandrel models with lengths up to 1800 mm. In the case of the twin mandrel Doffer, after performing the first doffing operation, the machine proceeds to position itself on the second front of the winder and performs the second doffing operation. The Doffer then proceeds to transfer its load of up to 12+12 bobbins to Shuttle transport vehicles, intermediate buffers or ground carts, depending on the type of system.

All Salmoiraghi Doffers feature numerous sustainable and energy-saving technological solutions; this fact is indicated by the certified “Green Label” badge affixed to these machines

Operator safety is guaranteed by special sensors which protect the work area.

GALLERY

AGV DOFFERS

In the case of plants exhibiting engineering problems deriving from low aisle heights or other peculiar space restrictions that prevent the installation of suspended Doffers, ground-travelling IGV (Inertially Guided Vehicles) are used. These machines, the result of a sophisticated design covered by international patents, operate similarly to the Twin Doffers but use inertial guidance systems which guarantee millimetric positioning precision. Similarly to the suspended Doffers, they are designed to unload the bobbins on transfer devices for subsequent loading of overhead Shuttles, ground carts and intermediate storage systems.

GALLERY

DTY DOFFER

Salmoiraghi is highly active in the field of textured yarn bobbin handling; this field presents special problems requiring an innovative approach, both from the engineering and the necessary machinery standpoints.

A special machine (Doffing Robot – patented, registered trademark), capable of interfacing with any type of texturing machine, enters the machine aisle, doffs the produced bobbins, transfers them by means of special devices to an AGV (Automatically Guided Vehicle) integrated in an automated handling system including quality control, weighing, labelling, shape check, packing and sending to warehouse processes.

The Doffing Robot is equipped with highly reliable, low maintenance, purely mechanical bobbin pick-up devices.

Thanks to the flexibility and operational autonomy inherent in the concept of the machine, it is possible to serve both large and medium-sized production areas. Each solution is designed according to the specific features of the system.

GALLERY