INDUSTRIES

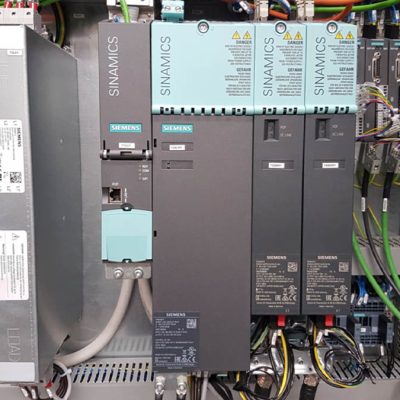

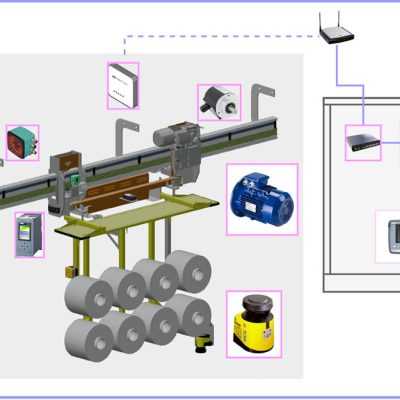

MACHINE CONTROL (LEVEL 1)

Il sistema di controllo dell'automazione è sviluppato su due livelli

Level 1 software (PLC based Siemens S7-1500 and HMI TP1200).

This architecture is responsible for:

- Control of the machinery movements

- Axes control

- Positioning

- Area co-ordination and interfacing of the machines

- Product transfer

- Handshake between machines

- Human-Machine Interface

- Parameter changing

- Machine state info

- Manual movement

- Safety

- Access control in segregated areas

- Laser scanner management

- Emergency circuits management

GALLERY

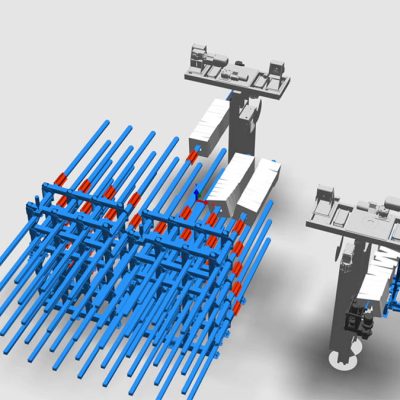

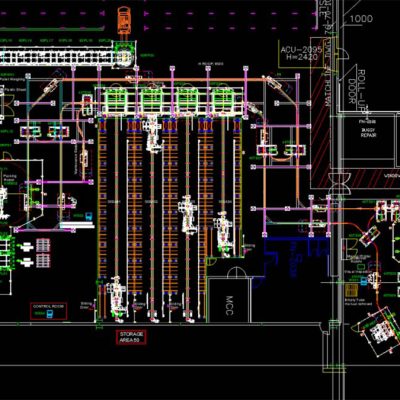

SYSTEM SUPERVISION (LEVEL 2)

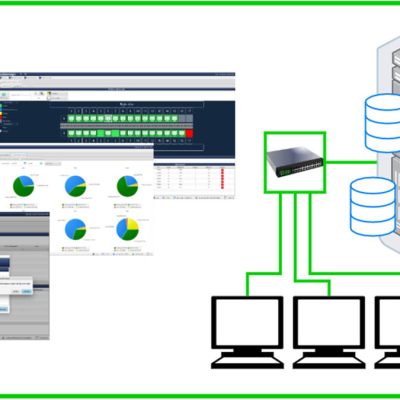

Level 2 software

(server and workstation based)

This architecture is responsible for:

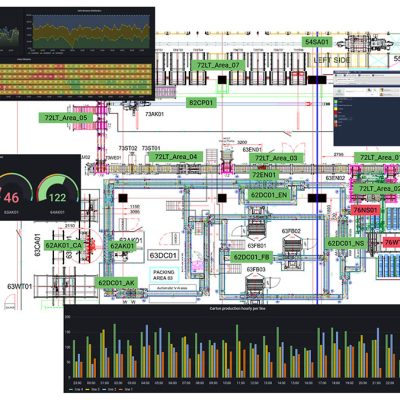

- Management of the mission (operated by Level 1)

- Co-ordinates the operations of the system areas

- Optimizes system resources by using them according to the operation priority to be carried out and minimizing the waiting times

- Label printing and weighing

- Data storage and handling

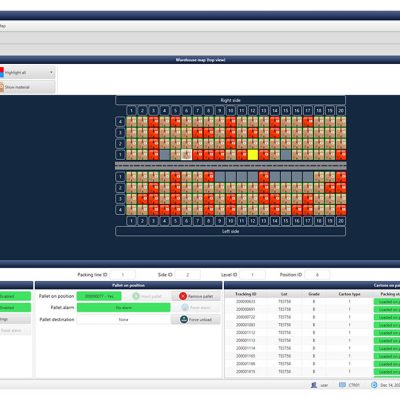

- Products tracking

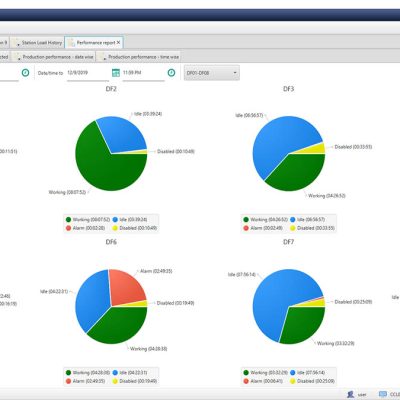

- Production and statistic reporting

- Server backup to guarantee the stability and security

of data and automation - Possibility of hot back up and hot plug in/out

- Monitoring of the system

- Report of possible malfunctions

- History of the machines Alarms (7 days)

- List of stopping time and stopping type

- Communication with the

- Customer ERP

- Receive additional information about product entering in the system

- Notify ERP about product going out of the system

- Possibility to create orders and missions from ERP directly

- User-System Interface

- Overview of the missions running

- Check and change of the storage state

- Enable/disable devices

- Manual creation of missions

GALLERY